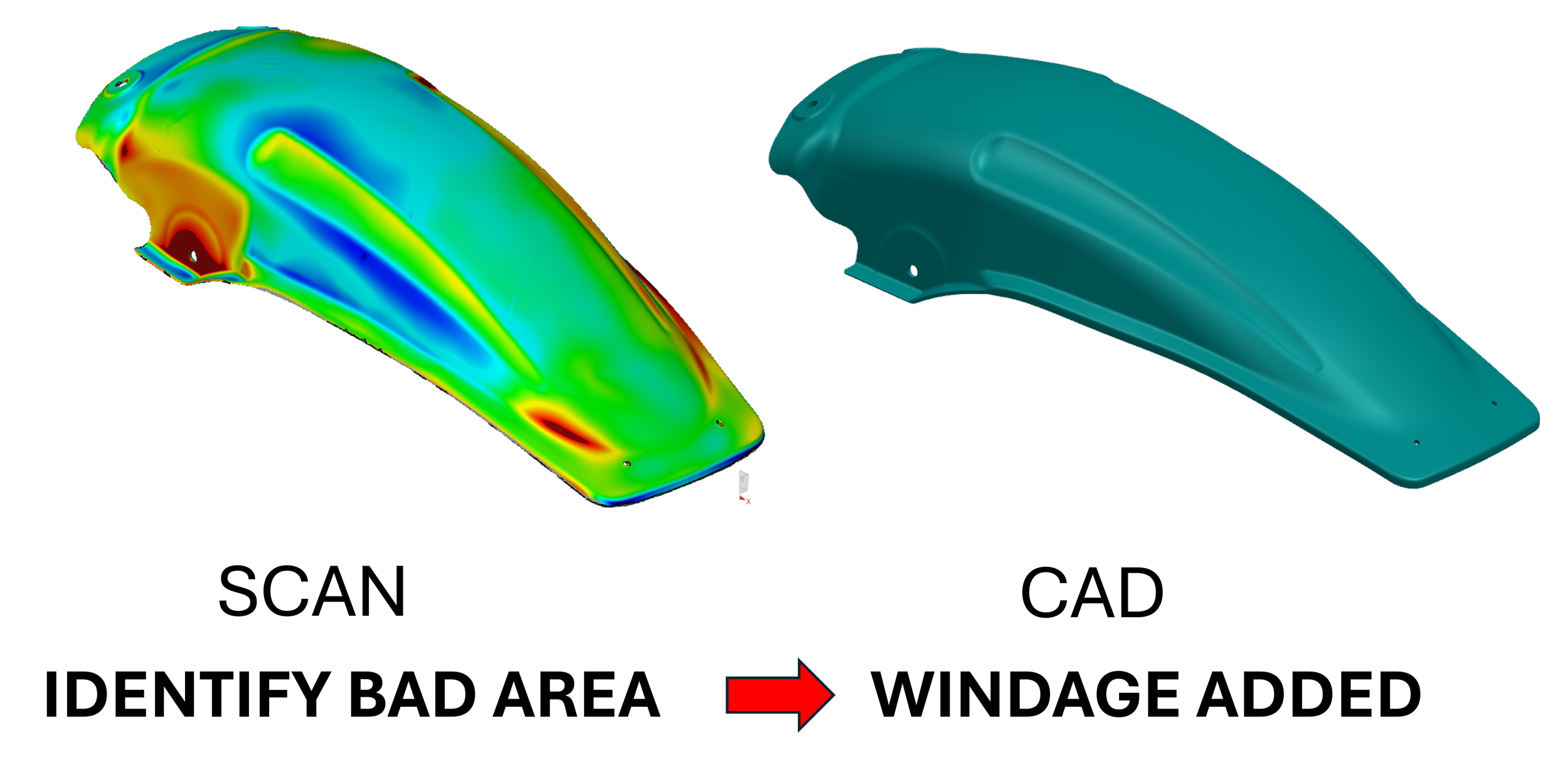

THE CHALLENGE OF REVERSE ENGINEERING IS FINDING THE DESIGN INTENT OR THE NOMINAL PART DEFINITION. THIS REQUIRES QUALITY 3D MEASUREMENT AND THE EXPERIENCE TO INTERPRET THE RESULTS.

Reverse Engineering

Reverse Engineering

Reverse engineering is a process that involves dissecting a product, system, or technology to understand its structure, function, and operation. This practice is commonly employed to gain insights into existing technology, replicate or enhance its capabilities, or identify potential vulnerabilities.

Methodology

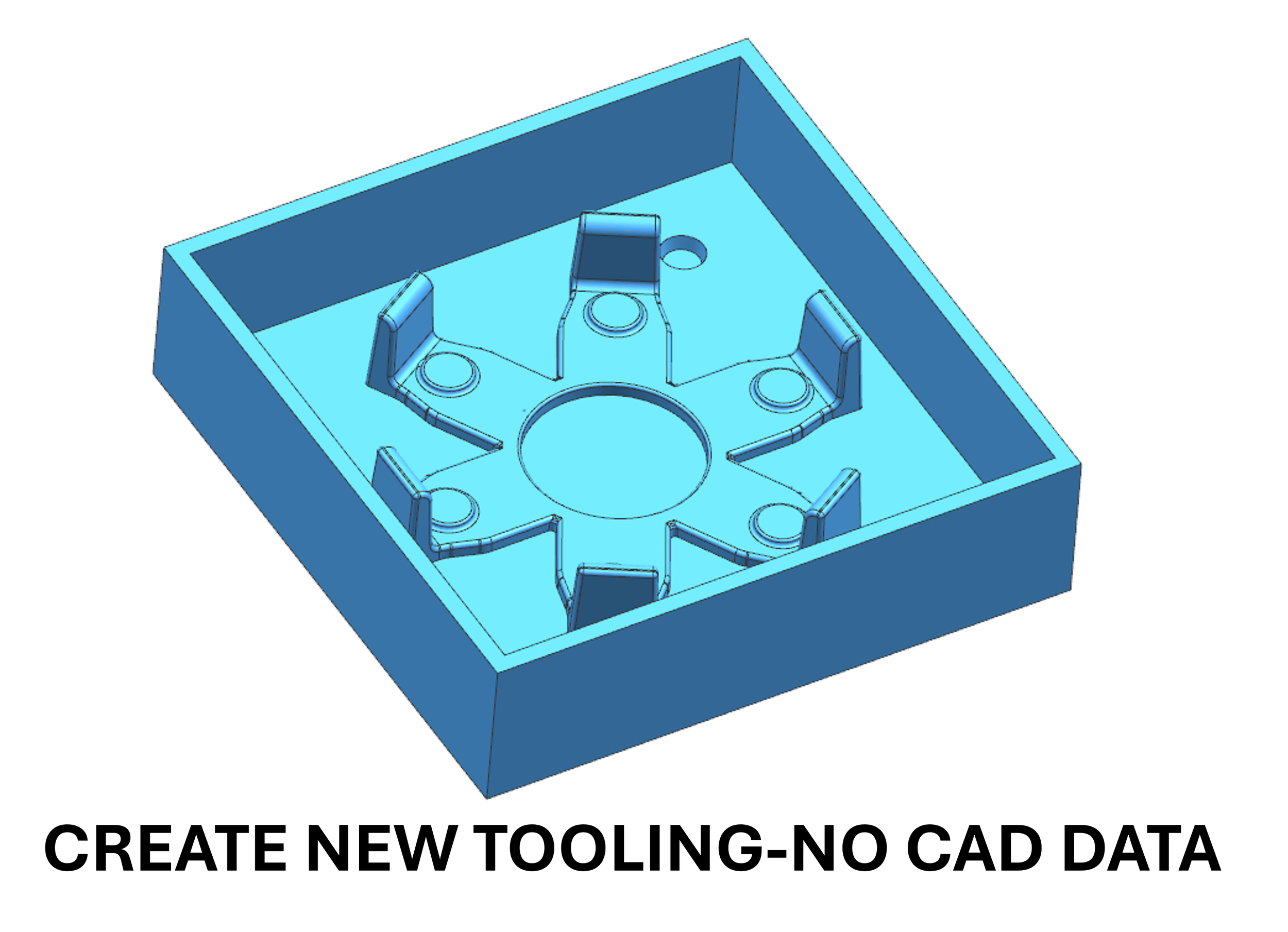

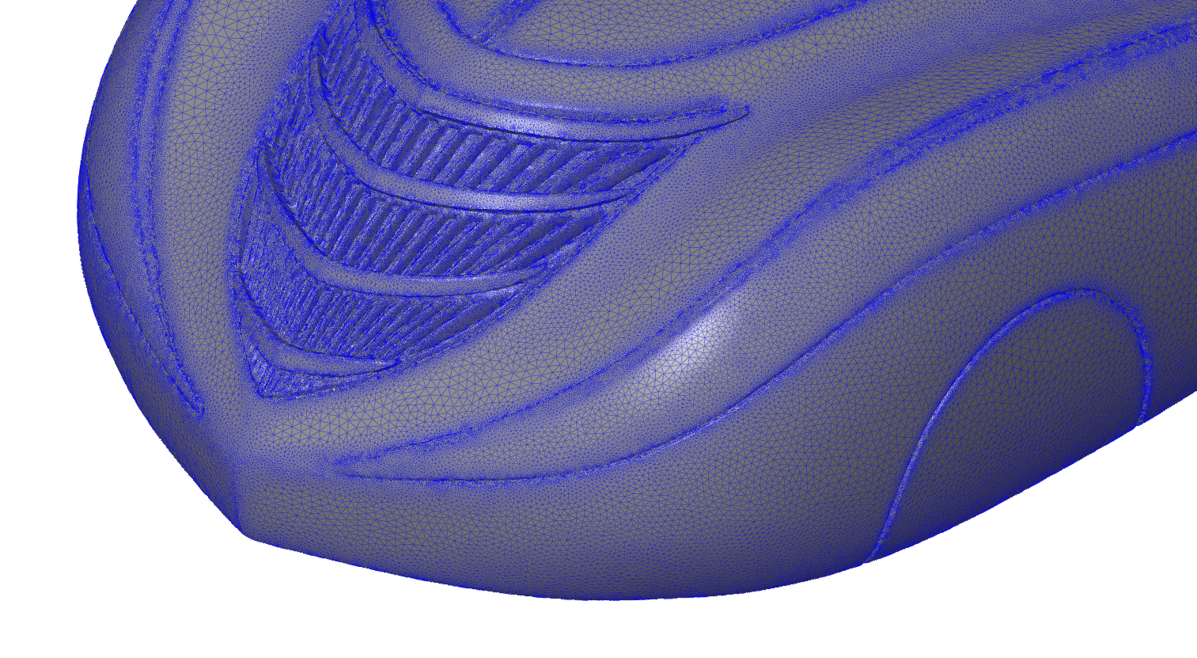

Reverse engineering typically involves a combination of technologies, tools, and human expertise. Engineers may disassemble a physical product, analyze its components, and use imaging and scanning technologies to create detailed digital models.

Product Understanding and Improvement

In the realm of product development, reverse engineering can provide valuable insights into the design and functionality of competitors' products. This understanding can inform the enhancement of existing products or the development of new, innovative solutions.

Ethics and Legal Considerations

Reverse engineering provides valuable insights and technological advancements, it is essential to navigate this practice within ethical and legal boundaries. Respecting intellectual property rights, adhering to licensing agreements, and avoiding unethical competitive practices are fundamental considerations in the application of reverse engineering is not the responsibility of Preferred Technologies. Preferred Technologies provides a measurement and design services, any and all use of that data is the responsibility of our clients who owns the data.